Mini- and Microenvironments in Battery Cell Production: Players, Patents and Potential

Mini- and microenvironments have the potential to make battery cell production more sustainable. These concepts are still a research topic. However, industrial activities are also increasing, with many of the players coming from Germany and Europe. An analysis of patent activities and players shows the research hot spots and geographical hot spots of this emerging technology.

Battery cell manufacturing requires a precisely controlled production environment to ensure consistently high quality and performance. Mini- and microenvironments provide a promising solution by controlling the contamination, temperature and humidity in a local environment, creating ideal conditions for sensitive process steps. This could make the large and energy-intensive clean and dry rooms used so far obsolete and significantly reduce the energy consumption of cell production.

The technology readiness level (TRL) of these approaches is currently mainly at the experimental to pilot stage, but the first applications in industry are already visible. A broader market introduction is expected between 2025 and 2028, as Plocher et al. predict.1

Important topics in research and development include energy-efficient air conditioning, the integration of the technology into existing production facilities, and scalability for mass production. Industry plays a crucial role in the further development of these technologies, as practical implementations and pilot projects can provide valuable insights into market readiness. Experience gained in semiconductor manufacturing with mini environments could serve as a basis for battery cell manufacturing.

Industrial structure and players

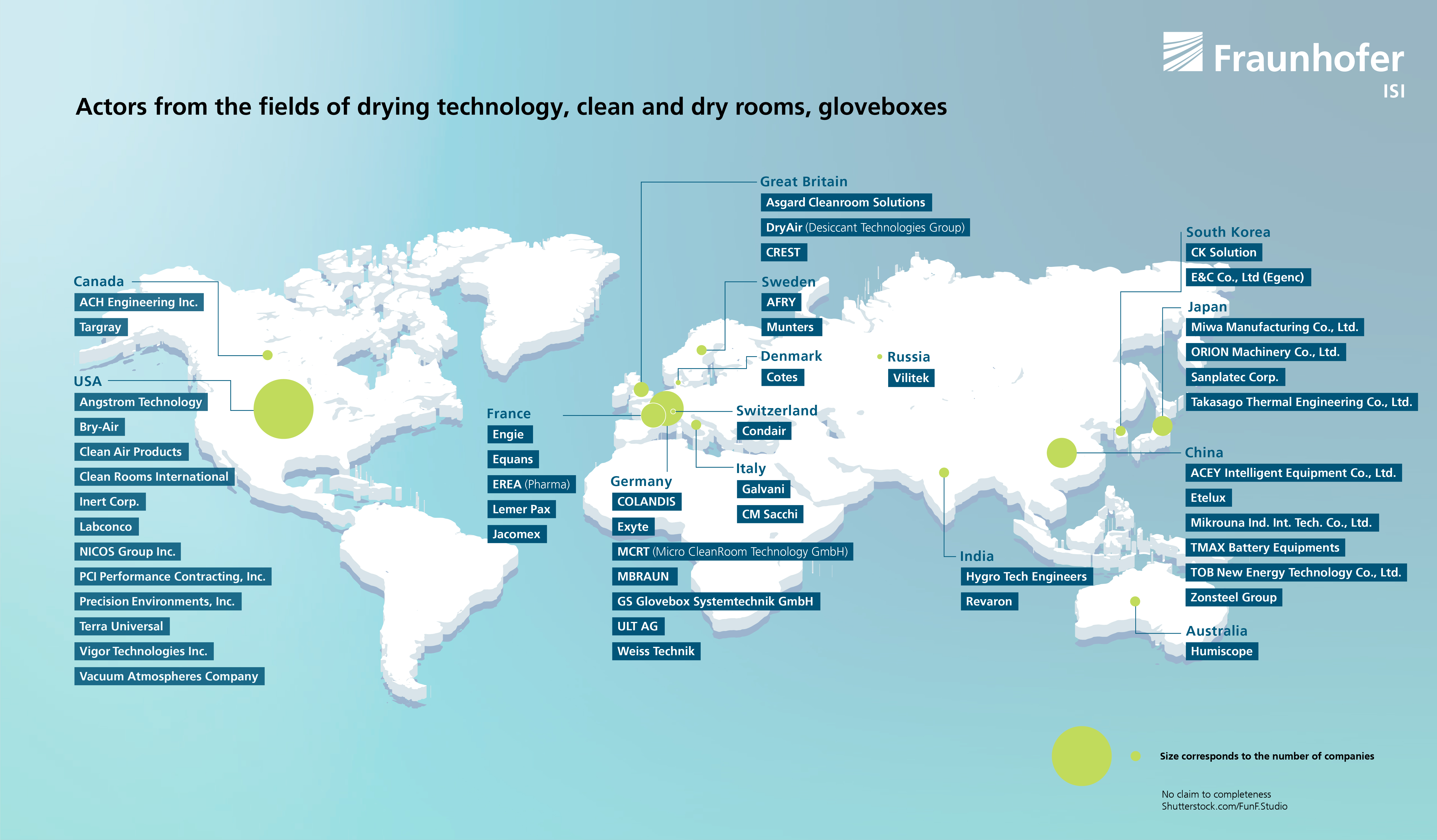

The development of mini- and microenvironments has not yet been characterized by a specific industry. Instead, several existing industries could be relevant for the subsequent development, manufacturing and supply. These include manufacturers of clean rooms and dry rooms, glove boxes, drying technology and automation technology. Depending on the concept of housing, drying and integration into production lines, mini- and microenvironments can be considered as intersections of these industries.

There are a large number of companies worldwide in the sections of clean rooms and dry rooms, drying technology and glove box technologies. Those companies are globally distributed and are mainly found in industrial regions such as the US, Europe and East Asia. The manufacturers of drying technology are distributed globally, without any particularly strong regional focus being apparent, while the glove box producers show a greater concentration in China, the US and Europe, particularly in Germany and France.

A significant proportion of the companies identified state that their products are also used in battery cell production. However, it is difficult to verify the specific link to large-scale projects such as giga factories, as no systematic data is available. It can be assumed that only a few companies in the field of drying technology and equipment are actually involved in gigafactories.

Some companies explicitly mention the concept of mini- and microenvironments with reference to battery cell production, with most of these players being based in Germany. It is not yet clear whether these suppliers actually deliver technologies that are compatible with the requirements of giga-scale battery cell production.

Patent landscape and focus of research and development on mini- and micronenvironments

The technology for mini- and microenvironments covers various patent classes, particularly in the fields of drying technology, ventilation and drying control, and logistics. An analysis of patent applications since 2000 shows the relevance of the following CPC classes:

- B01D53: air drying processes, particularly with adsorber materials.

- F24F3: air conditioning systems for clean rooms, especially for air treatment in such environments.

- H01M: Processes and means for direct energy conversion, e.g. batteries and fuel cells.

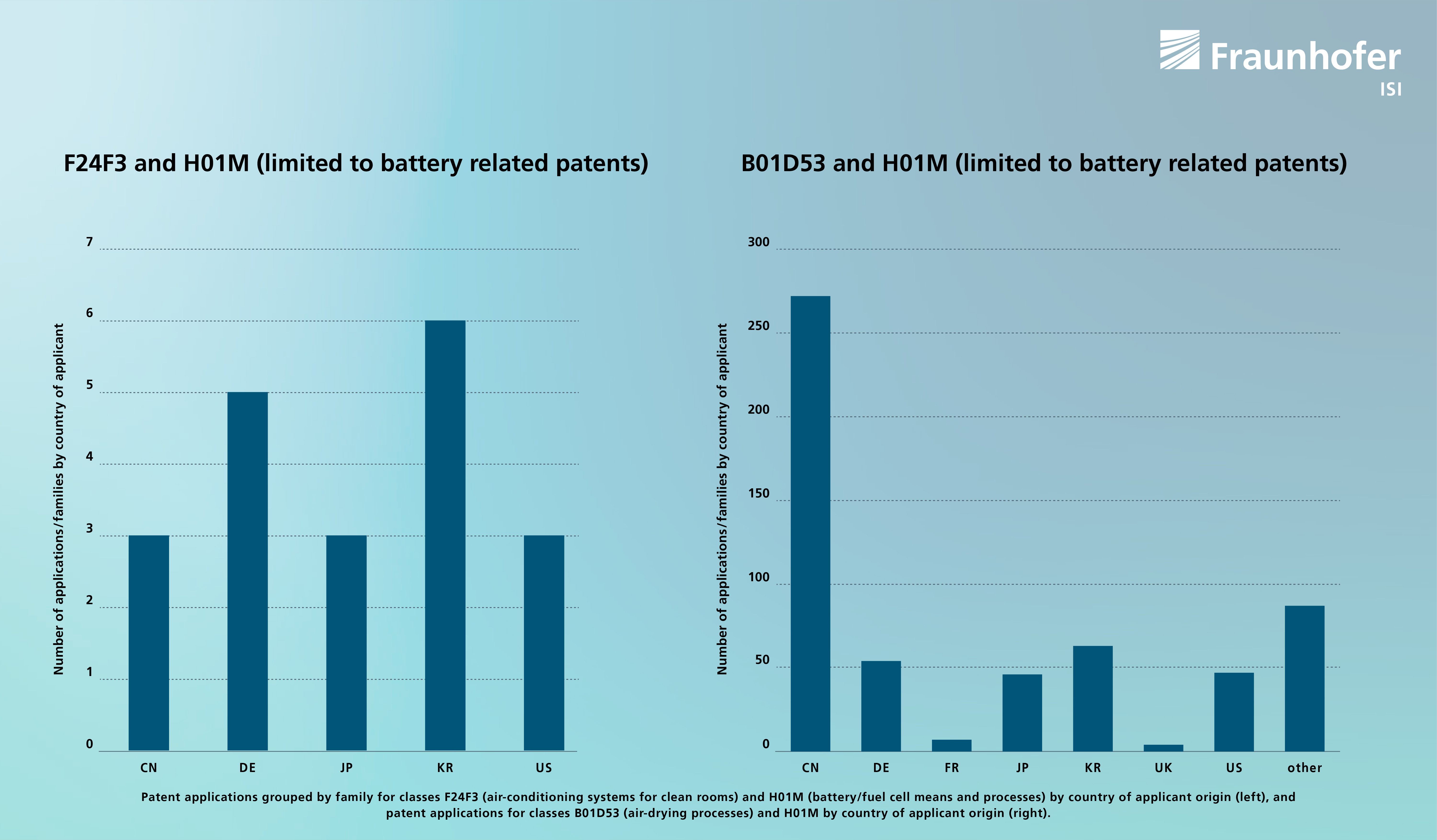

The combination of all three classes, B01D53, F24F3 and H01M, yields only a few patents, which mainly concern the air conditioning of fuel cells and EV battery packs, but have no direct relation to battery cell production.

Combining classes F24F3 and H01M shows more than 110 patent applications, but only 21 of these relate to battery production. Most of the applications come from Korea, Japan and Germany, with those from Korean companies such as Hyundai and Kolon Industries mainly relating to fuel cells. In Japan, Honda, Nissan and Panasonic are active, while in Germany, OEMs and suppliers such as Daimler and Mann+Hummel play an important role.

The combination of B01D53 and H01M covers more than 500 patent applications on topics such as battery drying, battery pack air conditioning and gas barrier materials. Chinese players such as CATL dominate here, followed by companies from Germany, Japan and South Korea, including Bosch and Mann+Hummel.

Most patent applications in the above-mentioned classes and combinations do not concern mini- and microenvironment concepts. These are only found in a small number of key patents: A total of 15 such applications were identified that emphasize modularity and individually air-conditioned process areas. The applicants for the key patents are mainly Japanese and Korean companies in the semiconductor and automotive industries (Hyundai, Toyota, Shinsung E&G, Kondoh Industries, EG Enc). Applications in the context of battery production are also represented by the German players Koerber Technologies and Fraunhofer.

The key patents for mini- and microenvironments can be divided into the following main topics:

1. Process area limitation (e.g. DE102021125515A1, KR20220046333A) for energy saving and material protection.

2. Humidity control (e.g. KR102342941B1, US20220373199A1) to dehumidify the production environment.

3. Toxicant and gas management (e.g. KR20220046333A, KR20200080654A) for filtering harmful gases.

4. Air circulation systems (e.g. JP2012052718A, KR20220046333A) for avoiding humid air.

5. Particle control and cleanroom technology (e.g. KR101611138B1, DE102021125515A1) for semiconductor production.

Some of these patents are aimed at battery cell production, but most of the applications concern semiconductor production. The earliest key patents (from 2007) focus on basic dehumidification systems. From 2015, the focus shifts to modular drying rooms, the separation of process rooms, pollutant control and the integration of automation and sensors to improve energy efficiency. In addition, there are several patents from semiconductor manufacturing that deal with transport technologies and lock techniques.

Scientific publications on Mini- and Microenvironments

The concept of mini- and microenvironments also plays a role in scientific publications. About 40 relevant publications in scientific journals could be identified. The majority of these studies also relate to semiconductor manufacturing, while only four studies examine mini- and microenvironments in battery manufacturing. Most of the publications come from industrial companies such as Global Foundries and NEC, as well as from research institutions such as Taipei University and the University of Seoul.

The term “minienvironment” is used differently in the publications, e.g. as a physically separate section (such as transport boxes) or as the air volume around objects such as wafers. According to the publication research, the research field of mini- and microenvironments has existed for about 30 years. In semiconductor manufacturing, the focus of scientific work is often on the spatial distribution of impurities, especially in automated transport boxes. A reference to battery production first appears in 2017. The explicit scientific investigation of mini- and microenvironments in battery cell manufacturing has only intensified since 2023 through work by Fraunhofer and RWTH Aachen University.

Outlook

The development of mini- and microenvironments is still in the phase of industry-related research. However, the implementation in the first industrial production plants could take place in the coming years due to many parallels to the semiconductor industry. The know-how for this lies predominantly in Asia, but Germany is very well positioned in the section of air conditioning technology and air drying due to a high patent share and local industrial companies. Targeted measures such as the SynBatt program of the German Federal Ministry of Education and Research are currently funding several consortia to further develop the concept for battery cell production.2 This gives rise to justified hope that Germany can play a successful role in the commercialization of the technology and thus offer further opportunities to improve the ecological sustainability of battery production in the future.

Resources

- Plocher et al, Mini-Environments In Lithium-Ion Battery Cell Production: A Survey On Current State, Challenges And Trends.

- Effizienzsteigerung und Nutzung von Synergieeffekten in der Batteriezellfertigung für die Elektromobilität: https://www.synbatt.com/

Funded by the German Federal Ministry of Education and Research (BMBF), grant number 03XP0540B.